Domestic pencils made by craftsmen from long-established factories

When was the last time you used a pencil?

Unless I use it in an art school or a profession, I have less of a chance to use a pencil in my daily life.

This is Yotsugi in Katsushika-ku, Tokyo.

It is a downtown area where stationery factories have been gathered for a long time.

Around Katsushika Ward, there are many town factories with very high standards of technology. However, in the recent market, overseas products occupy the majority, and the places where the technological capabilities that can be utilized are decreasing year by year.

We have decided to collaborate with the craftsman of the factory in Shitamanchi to develop the stationery made in Japan.

We asked the stationery maker “Hokusei Pencil” to make pencils.

The company was registered in 1951, and started to manufacture pencils in 1902. A long-established manufacturer that has been in business for over 100 years.

Although it is a long-established store, it is engaged in energetic activities from a new perspective, such as winning the category prize of the Japan Stationery Award for its original products and developing collaborative products with numerous manufacturers.

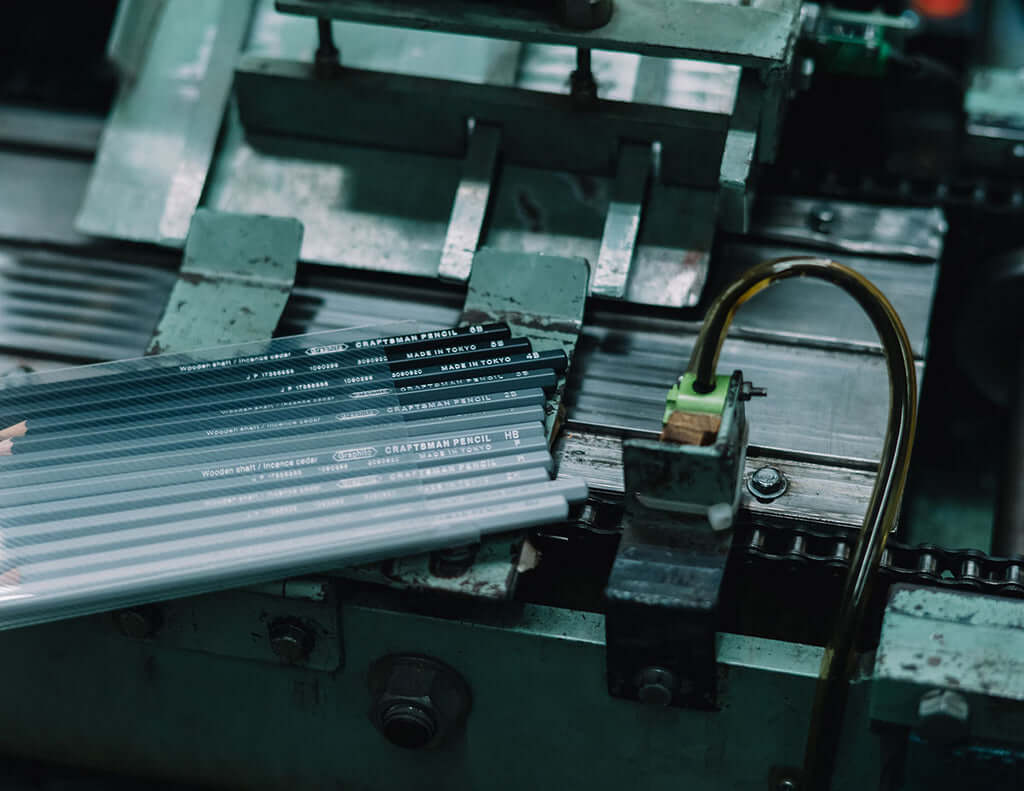

This time I made 12 kinds of pencils called ” CRAFTSMAN PENCIL ” for creators and illustrators. I would like to introduce a number of amazing techniques that should be called “craftsmanship”.

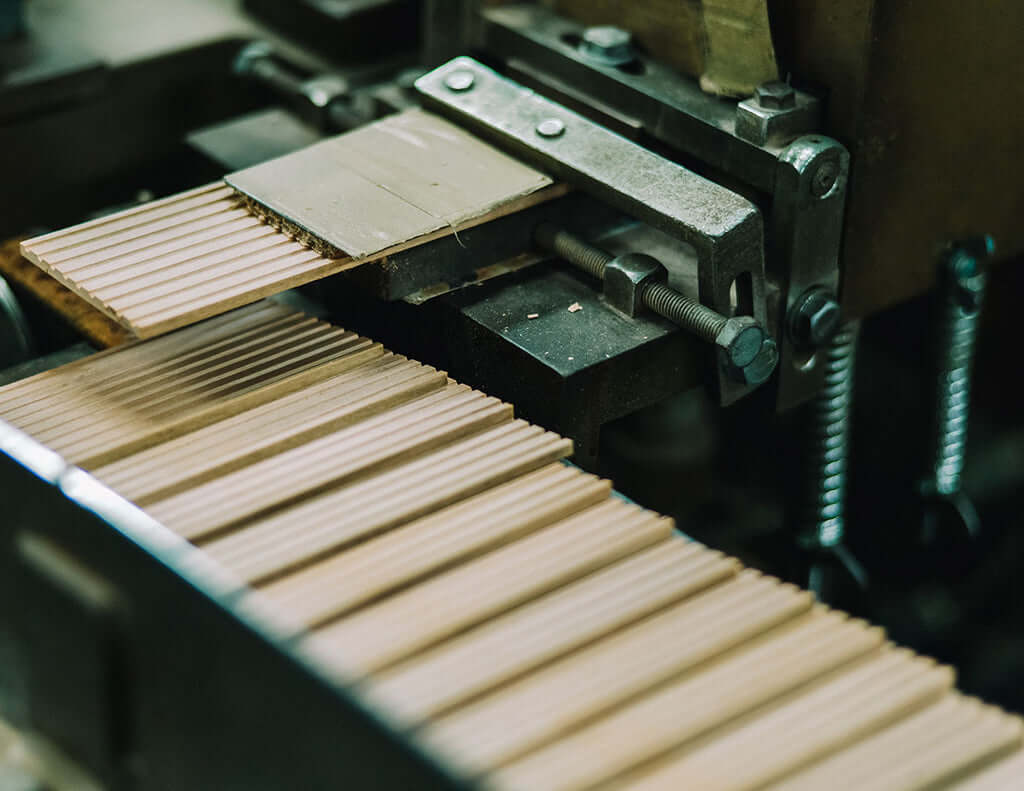

The first step is to make a pencil.

I usually use a stick-shaped pencil, but at the beginning of manufacturing, I start by sticking two wooden boards called “slats” together.

This time, we are using a wood called incense cedar, which means “fragrance”. It is no exaggeration to say that the wood is ideal for pencils because of its ease of processing, durability, and the beauty of the wood grain.

Incense cedar is often used for old-fashioned domestic pencils, and many people may feel nostalgic when they smell this pencil.

Carve a groove in these slats, set a mechanical pencil and stick them together.

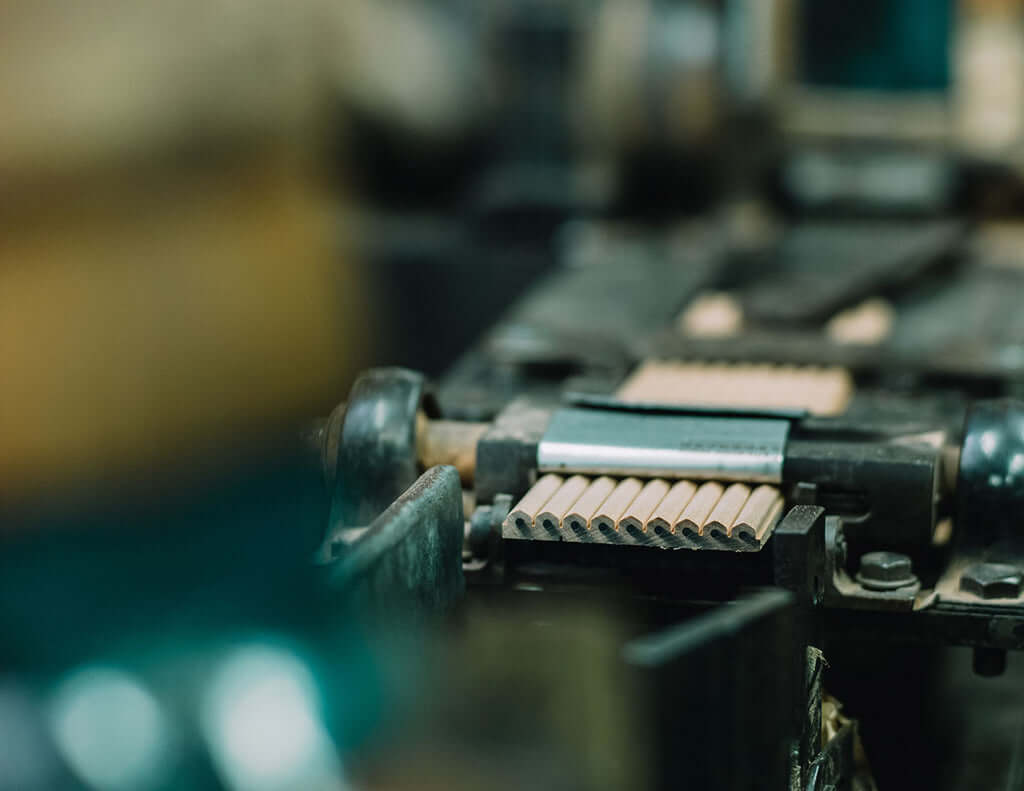

The pencil lead used in CRAFTSMAN PENCIL is the only one in Japan that uses a domestic pencil lead.

The biggest feature of the domestic core is its drawing taste.

It has the characteristic that the core is softer than the general overseas core. Since graphite is easy to get on paper, it is ideal for drawing work such as drawing and illustration.

When making the finest pencils from overseas, we take the trouble to order this Japanese-made pencil lead, which shows the high quality of the pencils.

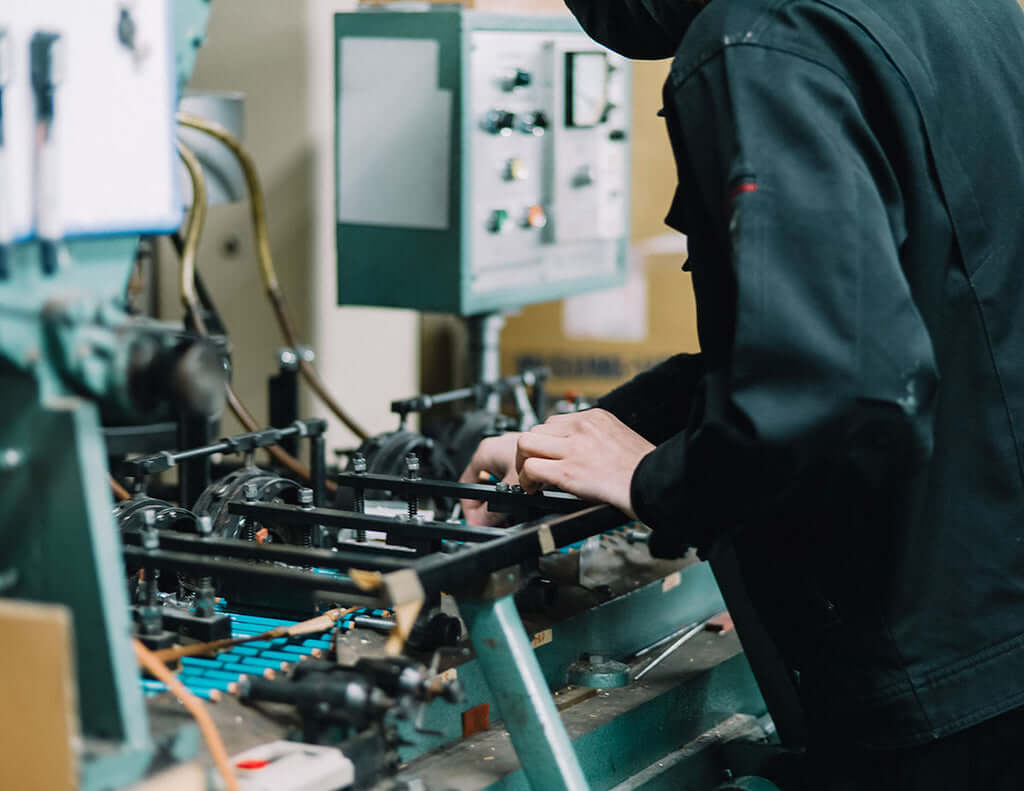

Next, we will enter a process called “pressing”.

This task is extremely delicate and requires a high degree of skill.

If the bonding is too strong, the wood will bend, and if it is too weak, the core inside will come off, making it difficult to adjust the force, and a wealth of experience is required before the optimum press can be performed.

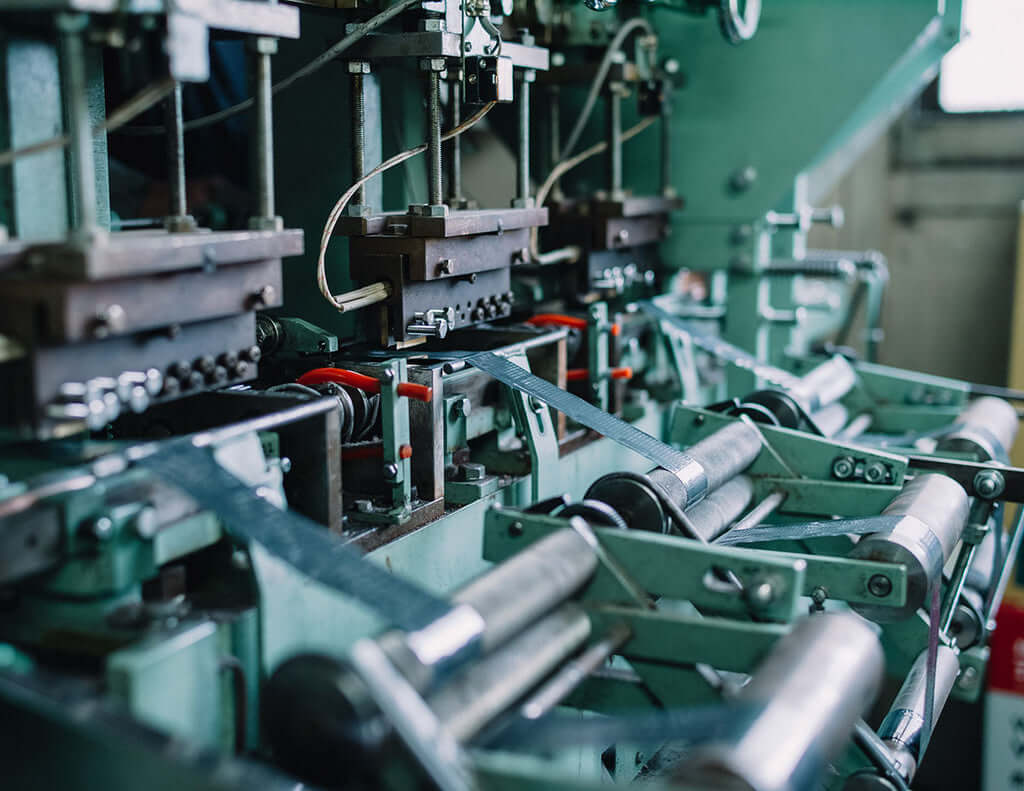

Finally, the pencil molding work is done and it is shaped into a familiar pencil shape.

Naturally, this work produces a lot of wood chips, but Hokusei Pencil is actively promoting the reuse of scraps generated when molding pencils.

This “ignition firewood” focuses on the fact that the pencil is coated with wax, and is a reborn scrap material as an ignition agent that easily catches fire and has little smoke.

Standard Products also sells this ignition firewood. It is a very convenient item for camping equipment, so please check it at the store.

Then moving on to painting the outer surface of the pencil.

I thought it was over after applying the ink once, but Mr. Hokusei Pencil applied the groundwork “6 times”. The grain of the pencil almost disappears even if it is painted once or twice, but as a result of continuing to verify that the ground color does not show through, it seems that it came to the conclusion of having it applied for 6 times.

Even if you can see the grain of wood for a while, you may feel like it, but I feel that you are a long-established manufacturer with an attitude of not compromising on the product at all.

At the CRAFTSMAN PENCIL 12 set, we asked you to paint the outer surface of pencils from 6B to 4H in 12 shades according to each core .

It seems that he had a lot of trouble in matching the colors, and it was worth it, and when they were lined up, the gradation became very beautiful.

Even though it has been painted 6 times, this delicate color adjustment is just craftsmanship.

After painting, the design is finished by “stamping”.

In addition, there are all kinds of inspections for each process, such as core hardness and writing taste inspection, thickness measurement and grooving accuracy, bending inspection, eccentricity inspection, etc. until completion.

Thorough inspections are carried out to maintain high quality so that defective products do not appear by any chance.

If you compare the actual finished product with a general pencil, you will be amazed at how comfortable it is to draw.

Especially for those who draw drawings and illustrations, we would like you to try the difference in the comfort of drawing with these pencils.

At the store, we sell 12 pencils in a set, as well as products from 6B to F individually, so please take a look.